A forklift is a type of industrial vehicle used to move and transport heavy or bulky loads in confined spaces or warehouses. This device usually has two forks or arms that can lift the load from the ground and place it at different heights. Forklifts come in various types, manual, gasoline, gas, electric and diesel, and are used in various industries such as warehousing, manufacturing, construction and logistics.

The history of the forklift dates back to the early 20th century. This device, which is used in many industries and workplaces today, was first created as an innovation to meet the needs of transporting and moving heavy loads. Here we briefly review the history of the evolution of the forklift:

For inquiries about forklift price, contact our experts: 09134315128

What is a forklift?

-

The earliest ideas:

Before the invention of forklifts, workers in warehouses and workshops had to move heavy loads manually. This process was not only time-consuming but also dangerous.

To solve this problem, ideas were put forward to invent machines that could lift and move loads.

-

Invention of the forklift:

– The first forklift using an electric motor and movable forks was built in 1917 by Thomas Lippmann, an American engineer. This device was created as a means of transporting loads in factories and industrial warehouses.

– The early forklift had an electric motor and a set of forks that could lift heavy loads.

– After World War II, the use of forklifts in civilian industries increased dramatically, especially in warehouses, factories, and manufacturing plants.

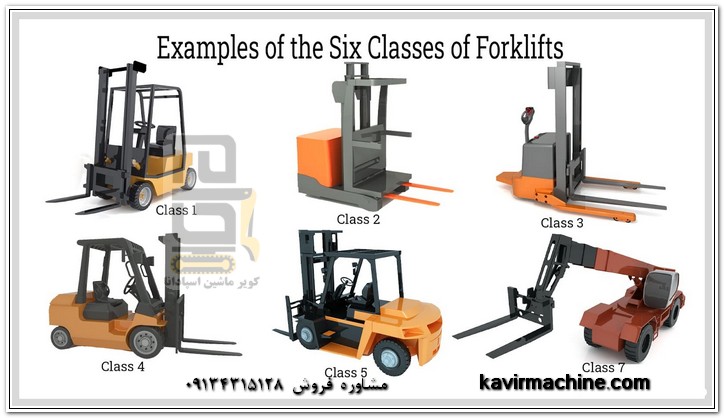

Types of forklifts

– Today, forklifts are produced in different types (manual, electric, diesel, gas-powered) and are equipped with more advanced systems such as artificial intelligence systems, remote control, and safety and anti-accident systems.

– Forklifts have become an essential part of logistics operations, warehousing, construction, and even civil engineering projects.

1. Manual Forklift (Manual Pallet Jack)

– Features: These types of forklifts are operated manually and do not require an engine. Using a lever, the operator can lift the pallets and move them to the desired location.

– Application: Suitable for limited spaces and small warehouses that need to move relatively light loads.

– Advantages: Low price, less manpower required, easy to use.

2. Electric forklift

– Features: These forklifts operate using an electric motor and do not require fossil fuels.

– Application: Suitable for indoor environments such as warehouses and large stores that require continuous operation. This type of forklift is suitable for moving heavy and bulky loads in closed spaces and clean, smoke-free environments.

– Advantages: Low noise, no air pollution, suitable for pollution-sensitive environments.

2.5 ton Toyota forklift price

3. Diesel forklift

– Features: These types of forklifts use a diesel engine to move and lift loads. They usually have higher power and are suitable for outdoor environments.

– Application: Suitable for working in open environments such as workshops, mines, factories and large outdoor warehouses.

– Advantages: High power, suitable for moving heavy loads, long service life.

– Disadvantages: Air pollution, loud noise.

4. Gas forklift

– Features: These types of forklifts use liquefied petroleum gas (LPG) to move.

– Application: Suitable for use in indoor and outdoor environments that require medium power and low emissions.

– Advantages: Less polluting than diesel models, suitable for use in indoor and outdoor spaces, lower cost than electric models.

– Disadvantages: They may still not be as quiet as electric models.

5. Mobile forklift (elevating or lifting)

– Features: These types of forklifts are capable of lifting loads to very high heights.

– Application: I Horse for loading and unloading operations at high altitudes or in warehouses that require high-altitude arrangement.

– Advantages: Ability to reach high heights, suitable for warehouses with multiple floors.

6. Stacker Forklift

– Features: Stackers are similar to manual forklifts, but have the ability to lift loads to higher heights.

– Application: Suitable for use in warehouses and places with limited space that require moving palletized loads and placing them at different heights.

Komatsu 3.5 ton forklift price

7. Rotating Forklift

– Features: These types of forklifts have the ability to rotate the forks, which allows them to move loads with special and complex shapes.

– Application: Suitable for loads with special dimensions or moving materials in limited space.

Each of these forklifts has its own features and applications, and the right choice depends on the type of work, available space, and the loads that need to be moved.

To buy all types of forklifts, contact our experts: 03137475120

The main features of a forklift are:

- High carrying capacity: Forklifts are capable of moving heavy loads.

- Operation in confined spaces: They are designed to operate in environments with tight and limited spaces.

- High height: These devices can place the load at different heights.

Forklifts are used to increase productivity in work environments and reduce time and manpower.

Summary:

Forklifts have evolved from a simple device in the early 20th century to advanced and vital devices in industry and commerce. They have been able to play a significant role in facilitating physical work, reducing risks, and increasing productivity in various industries.

Kavir Machine Espadana Company

In addition to new machinery and parts, Kavir Machine Espadana Company also offers used road construction and mining machinery with warranty and after-sales service, which are as follows:

Everdigm hydraulic hammer, Loader, Excavator, Dump truck, Lift truck, Backhoe, Drill Wagon, Grader, Bulldozer and…, for advice and prices, contact our experts at Contact.

Kavir Machine Espadana Company is registered in Isfahan Province with the purpose of importing road construction and mining machinery, and is also the only exclusive representative of Hyundai Everdigm Hydraulic Hammer in the entire country. The company’s management, relying on its decades of experience in the field of mining contracting and road construction and civil engineering projects, has expanded its activities in the field of importing and selling road construction and mining machinery, parts and related equipment. Therefore, realizing the lack of quality machinery in the country and despite problems such as sanctions and customs issues, we have started importing machinery directly from reputable global factories. In this regard, we can mention the signing of a cooperation agreement with Sumitomo Japan in 2003, which resulted in the import of the first series of Komatsu zero-ton machines to Iran. We hope that by relying on God Almighty and with the aim of achieving the satisfaction of our dear customers, we will be able to take our firm steps further for the prosperity of our dear Iran.

Kavir Machine Espadana Company Connection Roads

Isfahan, 3rd km of Zob Ahan Road, right side of the pass