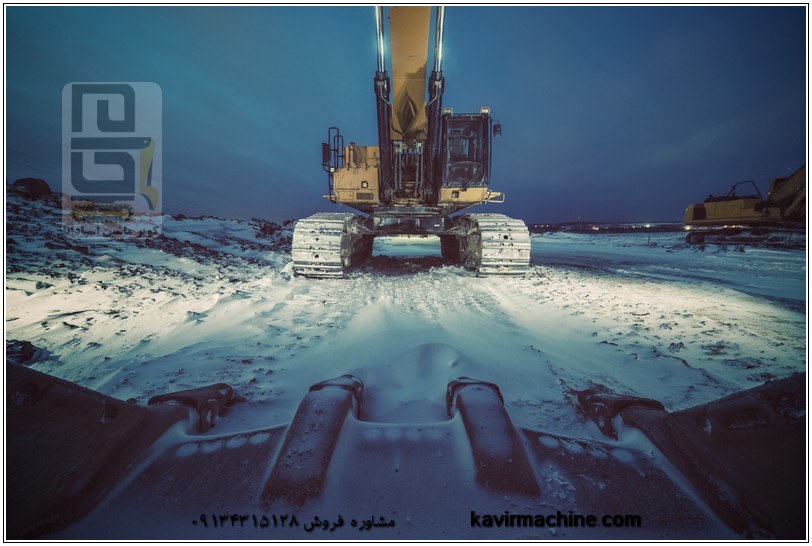

Maintenance of mining machinery is particularly important in winter due to the harsh environmental conditions. Extreme cold, freezing, and humidity can easily cause equipment failure and reduce productivity.

Mining machinery such as loaders, excavators, bulldozers, dump trucks, graders, and excavators are highly susceptible to damage in harsh working conditions, including very low temperatures in winter. The drop in temperature causes changes in the physical and chemical properties of lubricants, increases fuel viscosity, reduces battery efficiency, freezes parts, and decreases overall performance. Kavir Machine Espadana Company provides specialized mining machinery maintenance and repair services, ensuring the optimal performance of your equipment even in the harshest winter conditions.

For inquiries Excavator price, contact our experts: 09134315128

Maintenance of mining machinery

For this reason, preventive maintenance and adaptation of operating conditions to the cold season are essential. Here are the basic principles that must be followed to maintain these machines in the winter:

Mining machines and the use of oil suitable for cold weather:

1. Low-temperature lubrication

Importance:

At sub-zero temperatures, conventional oils and greases harden and do not flow properly in the system.

Recommended actions:

Use low-viscosity oils or those with API standards suitable for low temperatures.

Use special winter greases with a lithium or molybdenum disulfide base.

Lubricate movable joints periodically (weekly or daily, depending on conditions).

Antifreeze properties of heavy machinery in the cold:

2. Cooling system and antifreeze

Importance:

Failure to use proper antifreeze will cause cracking of the radiator, water pump, and cylinder block.

Recommended actions:

Use antifreeze with G-12 or G-13 standard for diesel engines.

Correct ratio of antifreeze to water (usually 50/50 or 60/40 depending on climatic conditions).

Test the freezing point of the coolant with an antifreeze tester.

Completely bleed the cooling system after filling.

Mining machinery and battery maintenance in winter:

3. Battery and electrical system

Importance:

In the cold, the capacity of batteries decreases and the internal resistance increases. Starting is difficult.

Recommended actions:

Use heavy-duty lead-acid batteries with appropriate amperage.

Check voltage and amperage daily with a multimeter or battery tester.

Clean battery terminals from sulfation.

Use a battery warmer at temperatures below -15 degrees.

Winter diesel fuel suitable for mining machinery:

4. Fuel and Fuel System

Importance:

Extreme cold causes the paraffin in diesel to crystallize and block fuel lines.

Recommended actions:

Use winter diesel or anti-gel additives such as Diesel Anti-Gel.

Drain water and sediment from the separator filter daily.

Check and replace the diesel filter periodically.

Warm the fuel tank in very cold environments (with an element or external heating).

Preheating a Diesel Engine in the Cold:

5. Preheating the Engine and Power Transmission

Importance:

Starting a cold engine without preheating causes severe wear of parts.

Recommended Actions:

Install a Block Heater or Oil Heater for preheating.

Use a Glow Plug or Intake Air Heater to assist in initial combustion.

Initial start-up in stationary mode for 10–15 minutes to reach operating temperature.

Operating heavy machinery in winter:

6. Tires, chains and driving in snow

Importance:

Ice and snow cause slipping, reduce traction and increase the risk of overturning.

Recommended actions:

Check the tire tread depth (at least 1.5 cm).

Use winter tires on icy roads.

Reduce tire pressure by up to 5% to increase contact area in slippery conditions.

Avoid rapid movement or sudden stops.

Defrosting the hydraulic system in mining machinery:

7. Hydraulic and power transmission systems

Importance:

Increasing oil viscosity slows down performance and puts extra pressure on hydraulic pumps.

Recommended actions:

Use a hydraulic oil with a suitable winter grade such as ISO VG 32 or 46 with a low Pour Point.

Initial warming up of the system before applying load.

Check the health of the control valves and leaks in the system.

For inquiries about excavator price and advice, contact our experts:03137475120

Winter Maintenance Checklist for Maintaining Mining Machinery:

8. Safety, Operator Training, and Winter Checklist

Additional Measures:

Train operators on the risks of slipping, reduced visibility, and extreme cold.

Wear warm clothing, non-slip gloves, and insulated safety shoes.

Install a cabin heater and proper ventilation system.

Prepare a daily winter checklist including checking antifreeze, fuel, oil, battery, tires, brakes, and lighting.

Conclusion:

Given the destructive effects of cold on the performance and useful life of mining machinery, maintenance of mining machinery in the cold requires implementing a winter preventive maintenance program that not only increases the productivity of mining operations, but also significantly reduces the costs of sudden stops and major repairs. Managing maintenance in cold mines requires careful equipment matching, logistical planning, and personnel training.

Kavir Machine Espadana Company

In addition to new machinery and parts, Kavir Machine Espadana Company also offers used road construction and mining machinery with warranty and after-sales service, which are as follows:

Everdigm hydraulic hammer, Loader, Excavator, Dump truck, Lift truck, Backhoe, Drill Wagon , Grader , Bulldozer and… , contact our experts at for advice and prices.

Kavir Machine Espadana Company is registered in Isfahan Province with the purpose of importing road construction and mining machinery, and is also the only exclusive representative of Hyundai Everdigm Hydraulic Hammer in the entire country. The company’s management, relying on its decades of experience in the field of mining contracting and road construction and civil engineering projects, has expanded its activities in the field of importing and selling road construction and mining machinery, parts and related equipment.

Therefore, realizing the lack of quality machinery in the country and despite problems such as sanctions and customs issues, we have started importing machinery directly from reputable global factories. In this regard, we can mention the signing of a cooperation agreement with Sumitomo Japan in 2003, which resulted in the import of the first series of Komatsu zero-ton machines to Iran. We hope that by relying on God Almighty and with the aim of achieving the satisfaction of our dear customers, we will be able to take our firm steps further for the prosperity of our dear Iran.

Kavir Machine Espadana Company Communication Roads

Isfahan, 3rd kilometer of Zob Ahan Road, right side crossing