Drilling rigs are usually used to access minerals, build tunnels, drill oil and gas wells, or even for underground engineering and construction work. Drilling rigs are widely used in various industries such as mining, oil, gas, water and tunneling.

All of these rigs have their own specific applications depending on the type of mine and drilling conditions and use different technologies to drill at different depths and conditions. Drilling machine refer to rigs that are used to perform drilling operations in lands, mines, wells and underground projects.

For Buy a drill wagon, contact our experts: 09134315128

Types of drilling rigs

Drilling rigs are divided into different types depending on the type of project and geological conditions. Here are some of the important types of drilling machines:

Rotary Drilling Machine

These machines are used to drill in hard rocks and in deep wells. In this type of drilling, a rotary drill is used that penetrates the ground by rotating and crushes the rocks.

Features:

– Ability to drill at great depths

– Suitable for drilling oil, gas and mining wells

– Use of rotary drill system and drilling mud to cool the drill and remove soil

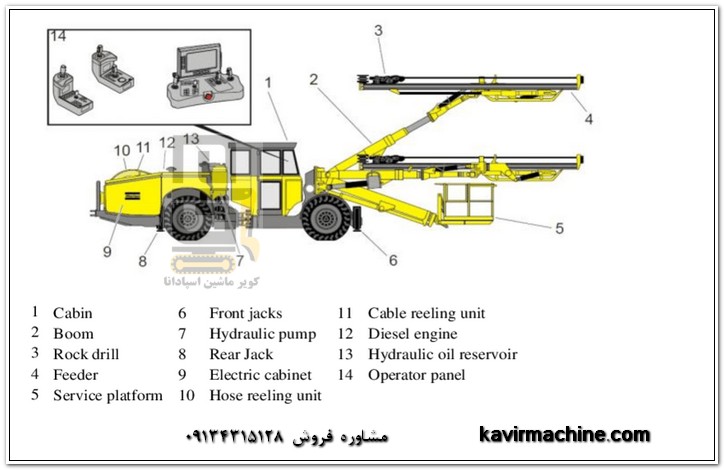

Jumbo Drill

Jumbo Drills for Mining Drilling They are used underground and are usually used in tunneling projects or for blasting holes in mines. These machines usually have multiple drilling arms that can drill several holes simultaneously.

Features:

– Multi-arm system for simultaneous drilling of multiple holes

– Designed for precision drilling in confined spaces

– Used in underground mining and tunneling

– Fast performance and high accuracy in blast hole drilling

Tunnel Boring Machine (TBM)

Tunnel boring machines (TBM) are used to dig tunnels in large underground projects. These devices are particularly used in large transportation projects such as subways, railways, and irrigation tunnels.

Features:

– Complex systems for drilling in hard rocks and tunneling

– Ability to dig tunnels continuously without the need for extensive operations after each drilling stage

– Designed for drilling in various geological conditions (soft, hard and sandy rocks)

– Used in tunneling projects, metro construction, and transportation infrastructure

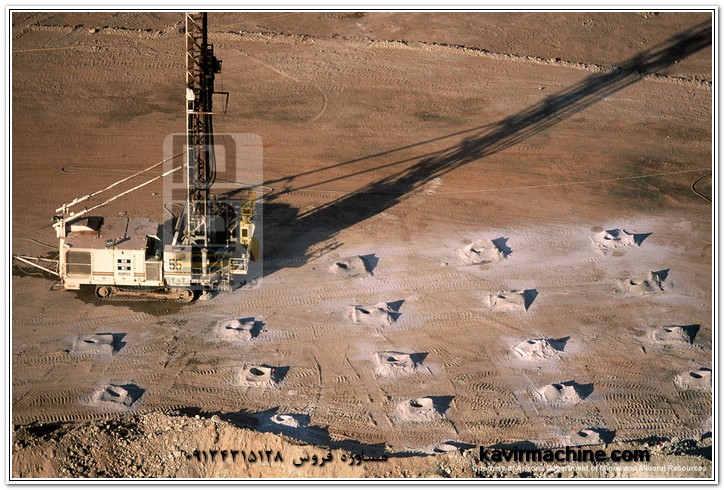

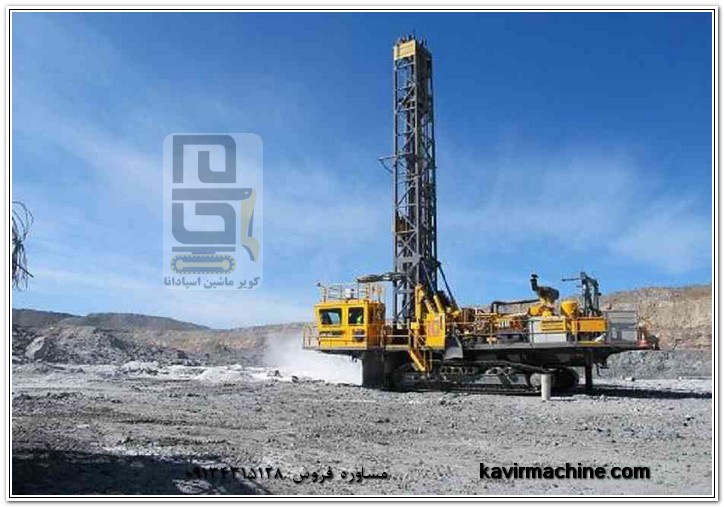

Blast Hole Drilling Machine

These machines are used to drill holes in which materials Explosives are used to break rocks. These devices are used in open pit mines to prepare rocks for mineral extraction.

Features:

– Vertical or horizontal hole drilling for use in blasting operations

– High power for drilling in hard and large rocks

– High speed and efficiency for open pit mines

Oil & Gas Drilling Rigs

These machines are used for drilling oil and gas wells. These machines are designed for drilling at great depths and in various geological conditions.

Features:

– Ability to drill at great depths (sometimes up to several kilometers)

– Designed for drilling in difficult and dangerous conditions

– Usually includes complex systems for pressure control, safety, and oil or gas extraction

Drill Wagon Price

Face Drilling Machine

These machines are usually used to drill into the walls of tunnels or underground mines. They are commonly used in tunneling projects and underground construction.

Features:

– Precise drilling in tunnel walls

– Suitable for tunnel preparation and mineral extraction

– Use in special conditions with limited space

Main components of the drilling machine

Drilling machines usually consist of several main parts that must work together to function properly:

- Engine: To provide the necessary power to rotate the drills and move Machine

- Drill: The main part used to drill into earth or rock. Different types of drills are used depending on the type of rock and soil.

- Hydraulic system: To move different parts of the machine, such as drilling arms or different machine systems

- Control system: To monitor and precisely control the drilling operation, which includes automatic or manual systems

- Moving mechanism: Allows the machine to move on or below the ground surface.

For inquiries Drill wagon price, contact our experts: 03137475120

Drilling machine applications

Drilling machines are used in various projects They have:

Mining: To extract minerals from the earth (such as gold, copper, coal)

Drilling oil and gas wells: To discover underground oil and gas resources

Construction of tunnels and underground roads: For transportation projects (metro, railway)

Drilling water wells: To access underground water resources

Drilling engineering projects: Such as digging wells and tunnels in large construction projects

Drill wagon price DI600 Sandvik

Drilling Machine Safety Tips

Drilling operations may be associated with risks due to harsh and dangerous conditions. Some important safety tips include:

– Operator Training: Drilling machine operators must have received the necessary training to be able to operate the machine safely and effectively.

– Use safety equipment: such as helmets, gloves, boots, and protective clothing

– Pressure and temperature control: to prevent accidents caused by high pressure or high temperature

– Regular inspection and maintenance: Drilling rigs should be inspected and maintained regularly to prevent breakdowns and accidents.

Conclusion

Drilling rigs play a vital role in mining, oil and gas projects, tunneling, and many other industries. Depending on the type of operation and geological conditions, different types of drilling rigs are designed and used for specific applications. These rigs generally help in drilling rocks, soils, or wells to extract mineral resources, oil, gas, and other minerals, and usually require advanced technologies and safety systems to achieve project objectives.

Kavir Machine Espadana Company

In addition to new machinery and parts, Kavir Machine Espadana Company also offers used road construction and mining machinery with warranty and after-sales service, as follows:

Everdigm hydraulic hammer, Loader, Excavator, Dump truck, Lift truck, Backhoe, Drill Wagon , Grader , Bulldozer and… , contact our experts at Contact .

Kavir Machine Espadana Company with the subject of importing a The company is registered in Isfahan province and is also the sole exclusive representative of Hyundai Everdigm Hydraulic Hammer in the entire country. The company’s management, relying on its decades of experience in mining contracting and road construction and civil engineering projects, has expanded its activities in the field of importing and selling road construction and mining machinery, parts and related equipment. Therefore, realizing the shortage of quality machinery in the country and despite problems such as sanctions and customs issues, it has started importing machinery directly from reputable global factories. In this regard, we can mention the signing of a cooperation agreement with Sumitomo Japan in 2003, which resulted in the import of the first series of Komatsu zero-ton machines to Iran. We hope that by relying on God Almighty and with the aim of achieving the satisfaction of our dear customers, we can take our firm steps more than ever for the prosperity of our dear Iran.

Kavir Machine Espadana Company Communication Roads

Isfahan, 3rd kilometer of Zob Ahan Road, right side crossing